QUALITY CONTROL

Quality Control In Production Process

Quality is the life of an enterprise, Huasheng is committed to the stability and continuous improvement of product quality, quality goals instill in the hearts of every employee. From mold design and development control to final pre-delivery inspection, product control and testing run through all production links to ensure that no nonconforming products are produced or delivered.

1. Design Control

Our design team, under the premise of meeting customer quality requirements, take the initiative to improve the process, and constantly improve the sense of use of products, so that our product quality has been in the leading position in the industry.

2. Incoming Material Control

We choose high quality steel products and purchase high quality materials, so that the use of higher intensity of products. Each batch of materials and spare parts are recorded in detail and can be traced.

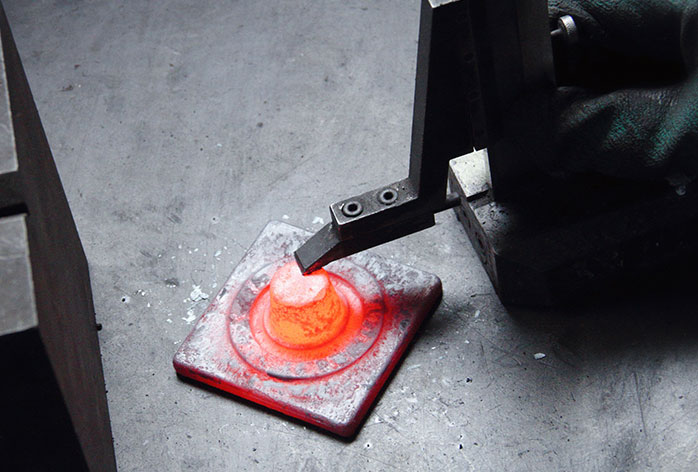

3. Forging Blank Dimension Inspection

Confirm that the dimensions are in accordance with the drawing.

4. Measurement of Finished Product

100% of the finished products will be measured and selected before delivery to ensure that the drawings are consistent with the requirements.

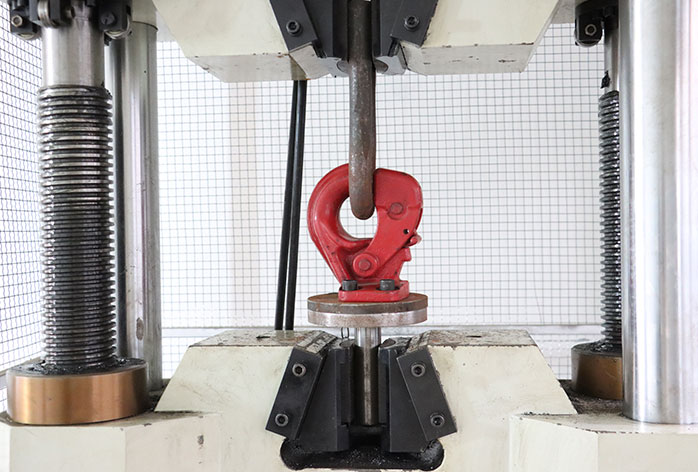

5. Tensile Test

Grand has a professional tensile testing machine, the staff of each batch of goods for tensile test, issued a tensile qualification, to ensure that the tensile qualified.

6. Hardness Testing

Each batch of goods shall be hardness tested to ensure that the hardness is acceptable.

7. Surface Smoke Test

Carry out smoke test for each batch of products with required surface treatment to ensure corrosion and rust resistance.

8. Packing Inspection

Check whether the product packaging meets the customer’s requirements and whether it meets the shipping or air quality requirements to ensure the integrity of the goods received by customers